Automotive

Equipment for the automotive industry

Cabins

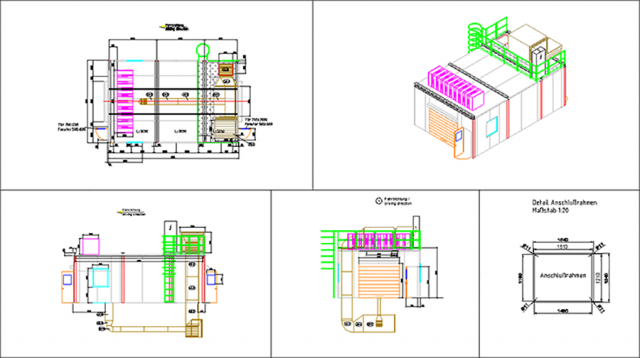

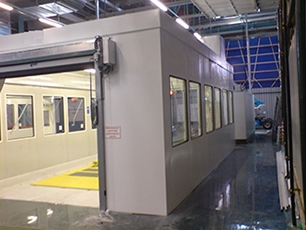

Sound proof cabins SSK-1

We assume the planning and implementation of sound insulating cabins for noisy equipment components. We do all planning for sound insulating cabins and related components such as: supply and extracted air units, multi leaf dampers, control system, lighting and air conditioning. The elements are supplied in galvanized finish or if preferred in powder - paint coatings in RAL colors. The necessary substructure, the statistics drafting, the design, as well as the total installation are if requested within our service.

When setting up noise generating machinery in an acoustic building another sound wave is produced with the reverberations on the buildings sides. If sound protection is to be effective the inner sides of the cabin have to be made of sound absorbing material. That way the reverberations on the acoustic walls and ceiling are minimized and further sound waves prevented. Furthermore the exterior ventilation openings have to be fitted with sound insulating splitters.

Sound proof cabins type SSK-1 are zinc plated. They are by default made of zinc for wall and ceilings panels with a thickness of approx. 80mm.design from the outside to the inside 1,5mm metal sheet, the absorption core made up of mineral wool (silicone-free) covered in non woven material, 1mm perforated steel plate. The wall panels are jammed and bolted to one another by means of floor rails and roof rings. The cabins will be provided with an inner horizontal steel structure according to statistic requirements. The whole construction I not flammable according to DIN 4102 Class A1. All tanks are bonded by tongue and groove joints.

The interconnection is achieved by a tongue and groove system. The installation on the floor frames is done in a U shape ring.

The cabin has a static essential steel structure of rectangular profile which is introduced in the zinc sound proof elements. The steel structure is positioned in such a way, so that it may carry further loads apart from its own weight. The whole structure is adjusted and the joints sealed. The cabins are provided with the necessary access doors and also especially in the front and back there are two automatic gates. To look into the cabin these gates can be partly transparent. Sight windows can also be placed to the sides.

The cabins can have the following equipment:

• easily accessible and tight closing door with or without glazing,

• lifting doors operated manually or electrically,

• flat toughened safety glass panes, laminated safety glass panes,multi glass safety pane for breakthrough prevention,

• inner horizontal steel construction to meet the statistic requirements needed for the cabin,

• Openings round, square,

• accessibility of the cabin roof,

• Powder coating of the outer surface in RAL colors of your choice,

• supply and extracted air system with fans, sound proof, designed according to requirements,

• lighting with PE moisture proof lights 1*58W or 2*58W, AP toggle switches, AP fuse distributor, cable incl galvanized cable channels